Commercial food equipment: Uncovering opportunities

We’re not restaurateurs, but we relish being a secret ingredient behind successful kitchens.

Through our work, Design Central has been in more kitchens—and types of kitchens—than perhaps anyone else in our industry. We’ve worked on many commercial food equipment projects that have benefited users and customers in restaurants, K-12 schools, grocery stores, the hospitality industry and more.

In other words, we’ve gained quite a bit of insight into food and how it’s prepared. And with each project, one of our fundamental goals remains the same: Uncover opportunities that better improve the experience of those who prepare food. This means improved products (including food), processes, and, of course, profits for our clients. Let’s take a look at how we do it.

Safety and efficiency are critical to equipment’s success

Food equipment, in its simplest form, is created to do a job: safely prepare food. Who touches the food, how long it takes to reach the customer, and what regulations are at play all factor into the equipment’s perceived effectiveness. We know this well and keep it in the forefront of our minds throughout our work.

Food equipment also is created to improve workflow. It’s expected that commercial food environments prepare food quickly and safely. Restaurants like Chick-fil-A, Kentucky Fried Chicken, McDonald’s and others are competing to prepare better food faster and for less. School kitchens are hustling to feed large groups of students during small windows of time. Busy grocery deli counters are rushing to meet demand.

Ultimately, food equipment manufacturers are looking to provide ways to support more efficient workflow while adhering to safety standards. But to provide solutions, we first have to understand the problems.

On-scene interviews + observation allow for thorough understanding

The foundation of our results lies in the research we do at the beginning of our process. From multiple angles, we gather intelligence so we can understand product use and workflow in an intimate way

We use contextual user-focused research to go into restaurants and schools and also kitchens with smaller footprints such as privately owned professional bakeries and eateries to talk directly to the users and stakeholders. What challenges do they encounter in their daily work? Where do they see potential for improvement?

For example, we spoke with those using the equipment to prepare food in order to discover unknown issues, which could then be shared throughout their respective organization. Interviews like these help lead to our next step: observation in the wild.

After interviewing stakeholders, we use the information we learned to inform what we discover during contextual observations. We observe, either in person or through video, the general workflow of the users and how they interact with specific equipment in their environments, including any and all workarounds. We take care to note, especially, if what they said in the interviews is supported by what happens throughout these observations.

In our work on a commercial stand mixer, for example, we interviewed, then observed professional bakers via video as they prepped goods overnight. What we watched was users stopping the mixer to scrape the sides of the bowl and gripping both sides of the bowl with some effort. What we saw was opportunity for improvement in the form of simple accessories that would make gripping and scraping the bowl easier and less time-intensive.

Interpreting insights leads to rich supply of opportunities

Finally, we analyze our findings, thoughtfully identifying patterns, gaps and insights that will lead us to successful solutions.

The client might know, for example, that their users vary in age, experience and education level. But understanding how that plays out on a daily basis can lead to a more productive and robust strategy moving forward.

Our research told us, for instance, that there are distinct regional differences in how kitchens prepare and store food in K-12 schools around the country. The insights enabled our clients to create features for refrigeration products for large and small school systems and budgets, rather than a one-size-fits-all approach.

Our insights also include a look at key trends, such as automation, as a way to support labor shortages, changes in the way food is ordered and delivered, and much, much more.

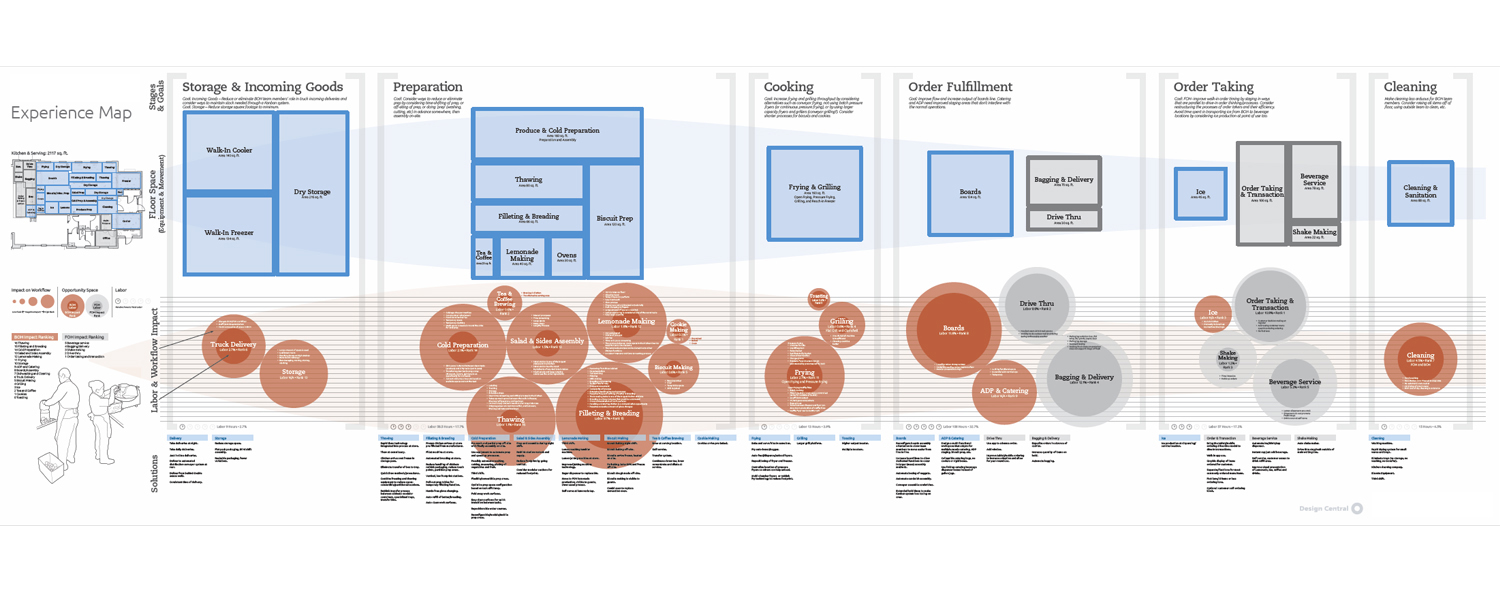

Ultimately and crucially, our insights lead to concrete and defined opportunities. Those can take many forms, including visualization, diagrams, rough mockups, working prototypes and more. We illustrate, as effectively as possible, where we see the potential for new product features, space-saving approaches, tech integration, process improvement and the like.

Our research process is in-depth, but it can be scalable, depending on the size of the project and the needs of each client. This is where powerful, research-backed ideas come from, and we’ve fine-tuned our collaborative process over decades to ensure that we deliver stellar results.

Research is a gold mine of possibilities. And the product development and brand differentiation opportunities that follow will lead to improvement on many fronts. We pride ourselves on being able to take any part of the process all the way through to production or implementation.

Whether your commercial food equipment opportunity calls for research, design, engineering or UX/UI, we’re armed with experience—and ready to go.

Contact Tim Friar for more about working with Design Central: t.friar@designcentral.com